ENGINE DEVELOPMENT

- FLUID-DYNAMICS-

|

|

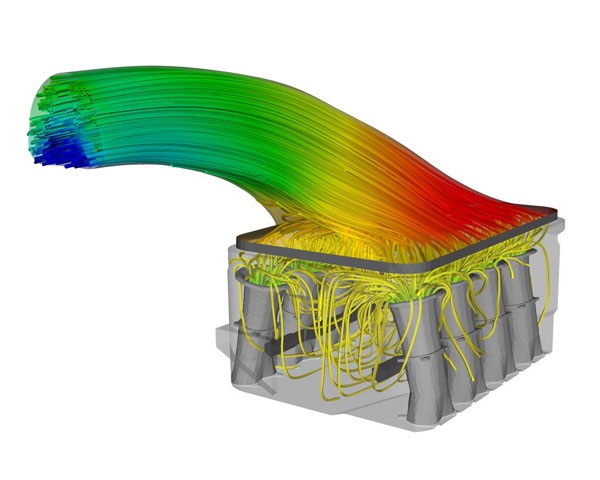

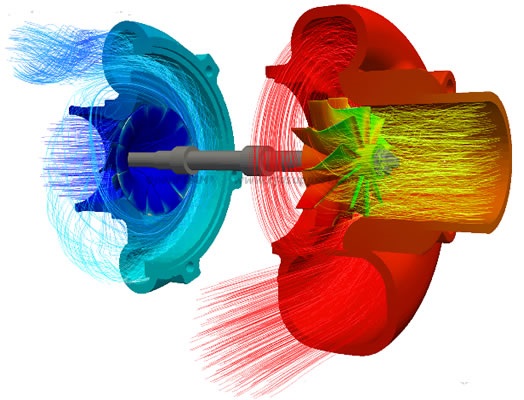

Our engine research and development activity focuses on two specific fields, one of which concerns the development of the entirety of the part of the engine regarding FLUID DYNAMICS. This part plays a key role in the performance and power delivery of each engine, especially for those intended for competitions.

The main goal of our work is therefore to obtain improvements in terms of general engine performance; all this is made possible thanks to the optimization of internal fluid dynamics carried out on the components and factors that negatively affect the volumetric efficiency, the trapping efficiency and the pumping losses of the motor. |

|

|

To develop the fluid dynamic portion we work individually on all the following engine components: |

|

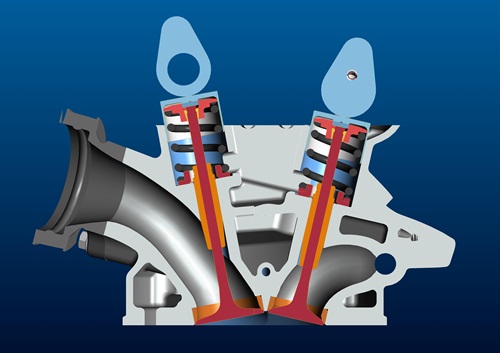

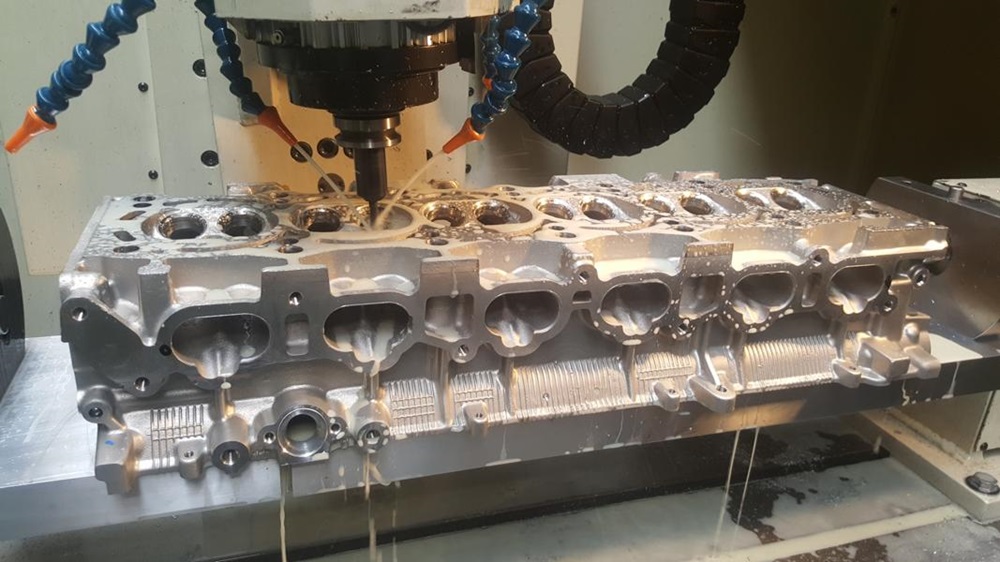

CYLINDER HEAD |

|

Depending on the requirements, we can design the complete head from scratch or modify the existing component. All mechanical machining on these parts is performed through CNC machining centers, up to 5 axis. |

|

|

THE FIRST INTAKE SYSTEMS |

|

All the components between the air intake and the head are examined. |

|

|

SUPERCHARGER SYSTEMS |

|

NIn the case of supercharged or turbocharged engines intended for racing applications, the coupling between turbo and engine is improved, the components that concern the intercoolers are optimized and the dynamics of the waste-gate valves, variable geometry and pop-off or dump valve are modified. We can also design and perform conversions from naturally aspirated engine to supercharged engines. In addition to turbochargers we can work with mechanically driven compressors, volumetric compressors (roots and screw type), twin turbo (series or parallel) and G-lader. |

|

|

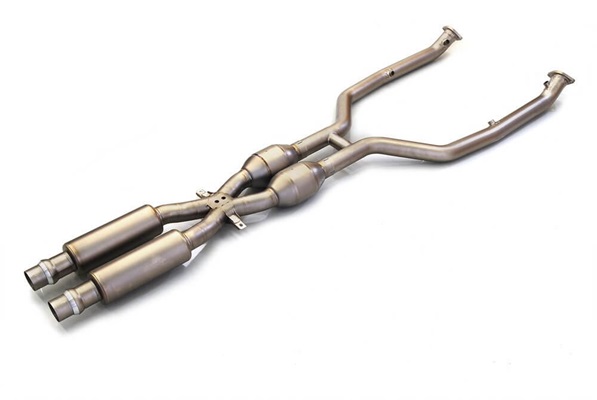

EXHAUST SYSTEMS |

|

The whole part including the exhaust system, from the engine outlet to the muffler can also be treated separately. |

|

|

Contact us for a free consultation, we will be happy to answer any questions; we can also prepare an estimate of the results that can be obtained based on the layout of your engine. |